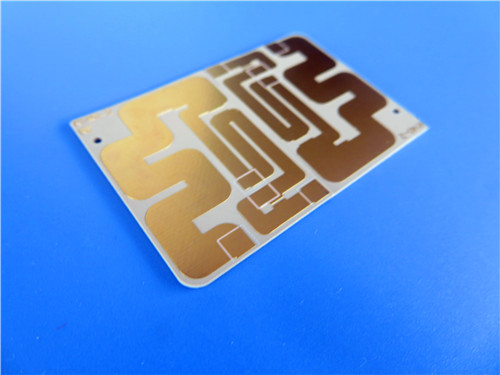

TFA300 Ultra-Thin RF PCB with 10mil Core and Immersion Gold Finish

1.Product Overview

The TFA300 is an aerospace-grade PTFE ceramic composite substrate that utilizes an innovative manufacturing process without traditional fiberglass reinforcement. With a dielectric constant of 3.0±0.04, this ultra-thin 0.3mm PCB delivers exceptional frequency stability and minimal dielectric loss, making it ideal for phased array antennas, airborne radar systems, and satellite communications.

2.Key Material Properties

Stable Dielectric Constant: 3.0±0.04 @10GHz

Ultra-Low Loss: 0.001 dissipation factor @10-20GHz

Temperature Stable: -8 ppm/°C ΔDk (-55°C to 150°C)

CTE Matched: 18/18/30 ppm/°C (X/Y/Z)

Thermal Conductivity: 0.6 W/mK

Moisture Resistance: 0.04% absorption

Flame Rated: UL 94-V0 compliant

3.PCB Construction Details

| Specification Parameter | Technical Detail |

|---|---|

| Base Material | TFA300 PTFE-Ceramic Composite |

| Layer Count | 2-Layer Rigid Construction |

| Board Dimensions | 65mm × 51mm (±0.15mm tolerance) |

| Minimum Trace Width/Space | 5/7 mils |

| Minimum Drilled Hole Size | 0.3mm |

| Via Type Support | Through-Hole Only (No Blind/Buried) |

| Overall Board Thickness | 0.3mm (10mil core + 35μm Cu) |

| Outer Layer Copper Weight | 1oz (35μm total) |

| Via Plating Thickness | 20μm |

| Surface Finish | Electroless Nickel Immersion Gold (ENIG) |

| Silkscreen Application | None (Top/Bottom) |

| Solder Mask Application | None (Top/Bottom) |

| Quality Assurance | 100% Electrical Testing |

4.PCB Stackup: 2-layer rigid PCB

Copper layer 1 - 35 μm

TFA300 Core - 0.254 mm (10mil)

Copper layer 2 - 35 μm

5.Board Statistics

Components: 12

Total Pads: 43

Thru Hole Pads: 27

Top SMT Pads: 16

Bottom SMT Pads: 0

Vias: 11

Nets: 2

6.Manufacturing & Quality Standards

Artwork Format: Gerber RS-274-X

Quality Standard: IPC-Class 2

Availability: Worldwide shipping

7.Technical Advantages

Fiberglass-Free Construction: Eliminates fiber weave effects for consistent RF performance

Multi-Dk Options: Available in 2.94, 3.0, 6.15 and 10.2 variants

Aerospace Reliability: Stable performance from -55°C to 288°C

Precision Manufacturing: Special lamination process ensures uniform dielectric properties

8.Target Applications

Aerospace equipment, space, in-cabin equipment, aircraft;

Microwaves, antennas, phase-sensitive antennas;

Early warning radars, airborne radars, etc.;

Phased array antennas, beamforming networks;

Satellite communications, navigation;

Power amplifiers.